Forming taps

Forming taps are tools for the non-cutting forming of internal threads. Formers do not have cutting edges or flutes (at best oil grooves for lubrication), but rather forming edges and pressure lugs with a polygonal profile. If the material fibres are cut through during thread cutting with a tap, thread forming only leads to a compression and deformation of the fibre course. This results in a work hardening of the material with a significantly increased material strength of the formed thread.

Formable materials

All cold-formable materials with good flow properties and a minimum elongation of 6 - 8 % are suitable for non-cutting forming. These include all light metals, pure and precious metals, soft steels (especially sheet metal, stampings and pressed parts), long-chipping non-ferrous metals such as copper and aluminium alloys, soft bronze, zinc and die-cast alloys, stainless and acid-resistant steels, etc.

Limits of thread forming

Naturally, brittle, short-chipping materials with minimal elongation, such as grey cast iron, cannot be cold-formed. Even high-strength steels above 1,000 N/mm² or AlSi alloys with more than 12% Si content can only be cold-formed with coated carbide forming taps if necessary. The limit of the maximum thread pitch that can still be formed is approx. 4 mm. Due to the sharp increase in torque, dimensions with an outside diameter of more than 60 mm are very difficult to form. However, larger diameters can be formed with internal lubricant supply and multiple outlets in the inlet cone.

Thread forming conditions

In addition to sufficient elongation of the material, good lubrication must be ensured during thread forming. As soon as the lubricating film breaks off, material welding-on can easily occur and thus lead to unclean thread surfaces, if not to tool breakage. For all materials, pressure-resistant special oils should preferably be used as cooling lubricants. No less important is the exact adherence to the recommended pre-bore diameters. The hole for thread forming must be drilled larger than the core hole diameter for thread cutting.

Advantages of thread forming

The forming tap allows higher cutting speeds compared to the tap. The tool life is considerably improved. No chip accumulation, therefore no chip jamming and no chip disposal. Higher material strength and better surface quality of the thread flanks. No pitch errors, no cutting, no inadmissible pre-stretching. Tight manufacturing tolerances must be observed. The gauge accuracy of the formed thread is always guaranteed. Only one type of former is required for blind and through hole threads and for a wide range of materials.

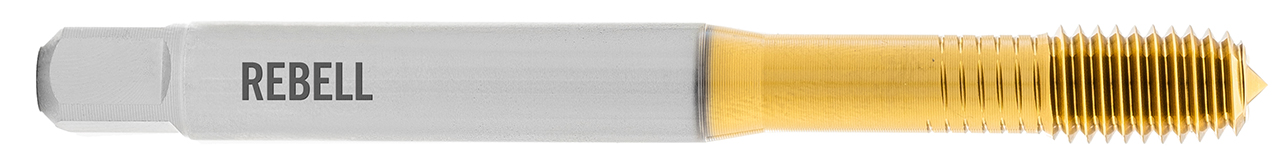

Forming taps without oil grooves

Type IGF is suitable for normal, less demanding forming applications up to 1.5 x diameter.

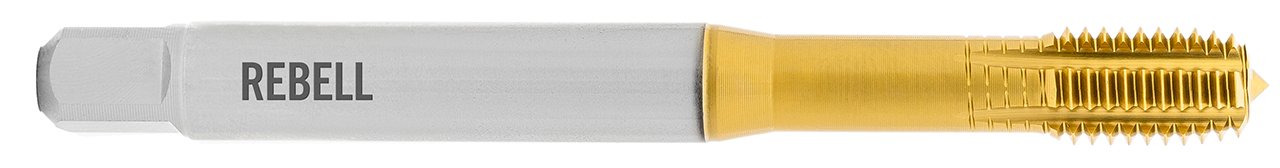

Forming taps with oil grooves

Type IGF-S, with oil grooves, is recommended for larger thread depths over 1.5 x diameter, for larger dimensions from 8 mm and always when an increased supply of lubricant is required, for example with through threads and/or horizontal operation.

Visit our Online Shop

You can also find all products in our online shop.